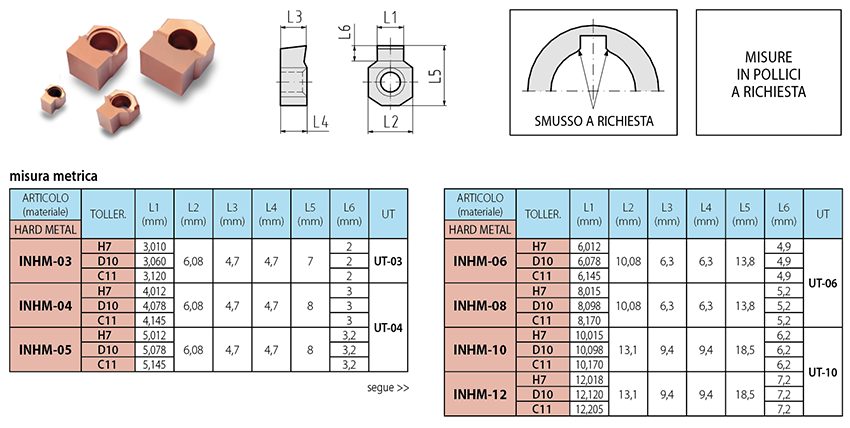

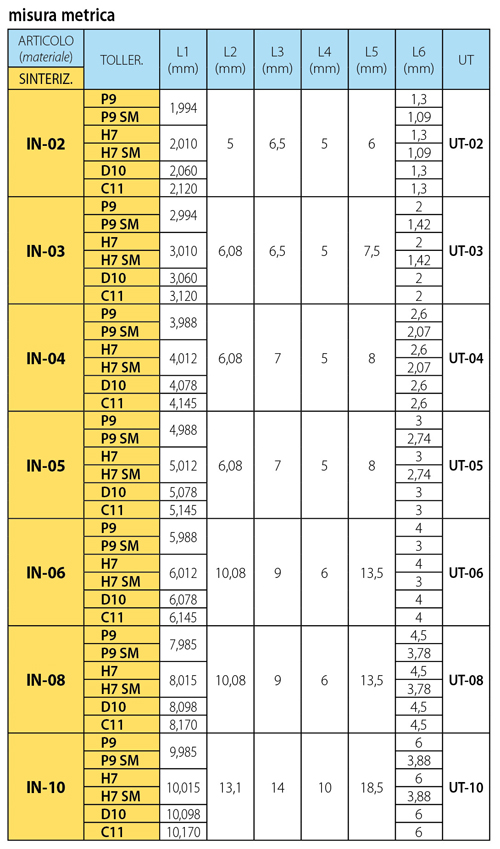

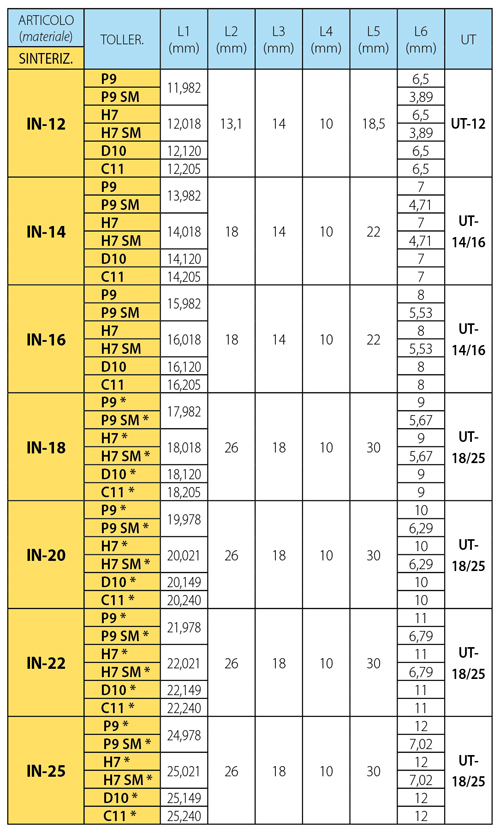

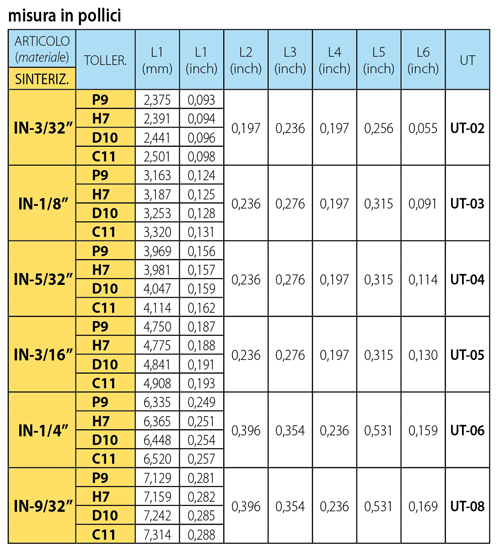

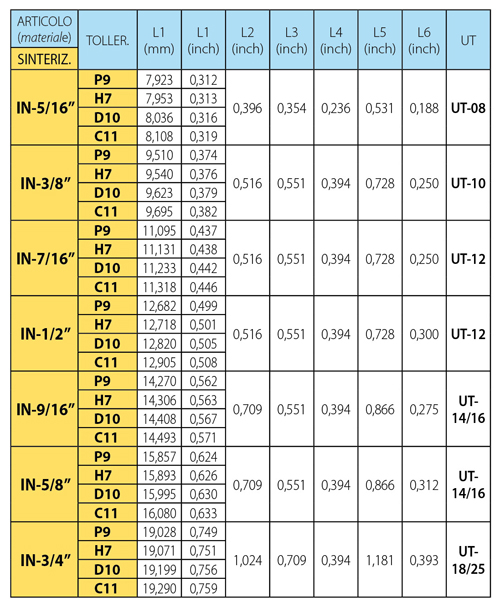

metric and inch measurements

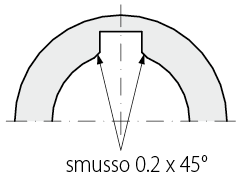

They are made of sintered steel with TiN coating. The type of steel and coating give the insert a high hardness that enables it to withstand excellently the repeated impacts involved in this type of machining. It is important to note that for some inserts, particularly inserts with P9 and H7 tolerances, chamfers of 0.2×45° can be made.

In this way, during and at the same time the execution of the keyway seat, any burrs formed during machining are eliminated.

The special shape of the inserts allows resharpening to be performed 2/3 times resulting in cost reduction. The insert sizes expressed in Fig. 3 are always available from stock.

Inserts are produced in metric and inch sizes

* In P6 and H7 tolerance versions, the insert can be requested with a chamfer of 0.2×45° at the point of intersection between the hole and broached slot walls, thus leaving the hole burr-free.